Removable Film Labels

Written by: BernauLena

|

|

Time to read 4 min

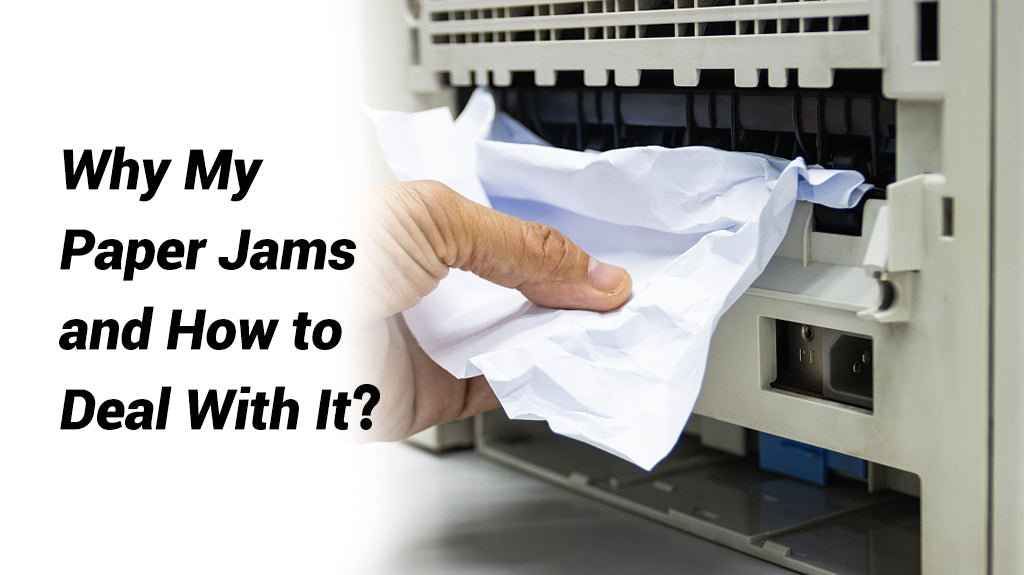

If you've ever had a piece of paper get stuck in the paper tray or inside the printer, you've experienced a paper jam. This common issue can be really annoying, especially when you are in a hurry or in the midst of a busy day. There are many reasons for paper jams. Here we list five common ones: wrong label size or type, poor label quality, overloaded paper tray, misaligned paper guides, and printer maintenance issues. By identifying and avoiding these common causes, you can minimize paper jams and ensure smoother printing. Now, Let’s dive into this issue!

Table of Content

Wrong Paper Size or Type

Using the incorrect label size or type is one of the most common causes of paper jams. If your labels do not fit your printer, they can get stuck and cause jams. Ensure the labels you purchase are compatible with your printer before loading them into the paper tray. If unsure, contact customer service to confirm the size and compatibility to avoid unnecessary time and financial losses.

The quality of labels significantly affects the smoothness of printing. Labels that are too thick, too thin, or too rough can cause feeding difficulties. To avoid such issues, purchase labels from reputable, large-scale companies. Companies with their own factories typically offer more stable supply chains and consistent label quality compared to those without stock because they have a completer control over the label quality. Such companies have been tested by market over time, ensuring reliable product quality.

Additionally, proper storage of labels is essential. Store them in a cool, dry, and well-ventilated place to prevent labels from becoming brittle, damp, or curled, which can also lead to paper jams.

Wow!Look at these!

Another common issue is overloading the paper tray or feeder with too many labels. This can make it difficult for the printer to pick up or separate the sheets, leading to multiple sheets being fed at once and causing jams. To avoid this, load an appropriate amount of labels into the tray, not exceeding the printer's maximum capacity. Before loading the labels, fan them to remove any dust that may have accumulated, preventing dust build-up inside the printer.

Paper jams can also result from improper removal of labels. Pulling or tearing labels forcefully from the wrong direction can damage the printer, leave paper residues, or cause further jams. When a paper jam occurs, you might feel nervous and tempted to pull or tear the stuck paper. However, try to avoid doing this as it can worsen the problem.

Paper guides in the paper tray or feeder are adjustable parts that help align the paper correctly into the printer. If the paper guide is too loose or too tight, it can cause the paper to skew or shift, resulting in jams. Ensure the paper guides are properly adjusted to avoid this issue.

Over time, dust can accumulate inside the printer and paper tray, and the print head and sensors may become dirty. These factors can reduce printer performance and cause jams. Regular maintenance and cleaning of your printer are crucial to avoid these issues.

While understanding the common causes of paper jams can help prevent them, it's also essential to know how to deal with a paper jam when it occurs. Follow these steps to safely remove the jammed paper and ensure smooth printing in the future:

1. Turn off the Printer: Ensure safe operation by turning off the printer.

2. Open the Cover: Gently open the printer cover and locate the jammed paper.

3. Remove the Jammed Paper: Carefully pull out the jammed paper. Use a swab or soft cloth to clean the machine and paper tray, checking for any paper residues.

4. Place the paper tray back: Carefully place the paper tray back into the printer, ensuring that the labels are correctly loaded without overfilling or misalignment.

5. Close the Printer Cover: Securely close the cover and power the printer back on.

6. Print a Test Page: To confirm that the jam has been fully resolved, print a test page.

Paper jams can be a real headache, but knowing their common causes and how to avoid them can make your printing process much smoother. Regular maintenance, choosing the right labels, and handling your printer with care can greatly reduce the chances of running into jams. And if a jam does happen, following the proper steps to clear it will keep your printer running like a charm. Keep these tips in mind, and you'll be printing hassle-free in no time!

About us

Betckey Premium Labels is a leading supplier of compatible direct thermal labels, committed to high-quality and eco-friendly products as well as competitive pricing. Now, our Amazon store ranks first in the US, Canada, and Western Europe with thousands of positive ratings. Visit betckey.com and get 10% off purchases over $150 with code Betckey10 and 15% off over $400 with code Betckey15. Sign up now and we'll send you a $5 discount code towards your first purchase. Shop with Betckey today!

Occasional paper jams are unlikely to cause serious damage to the machine and can be handled properly. However, if jams occur frequently and are addressed in a forceful manner, it may lead to damage to the paper tray and surrounding components. Furthermore, if the machine is already old, repeated jams can exacerbate these issues.

Check the printer carefully to see if there are any paper residues left. If so, clean the area gently with soft paper and remove any remaining paper.

If you want to buy thermal labels or sticker paper, you can check out more on our store

24/7 support team

Multiple Payment Methods

Worry-free shopping

Delivery in 3-7 business days

Be the first to know about label discounts,

product launches, and time-saving tips — subscribe now!

Are you 18 years old or older?

Sorry, the content of this store can't be seen by a younger audience. Come back when you're older.

We use these labels for Amazon UPC and they work fantastic!

We are very happy with the product and value for our small business

Camaj Fiber Arts.com

On time, package labels that are the right price! Thank you

Dymo 30256 Compatible Large Shipping Labels 2-5/16” x 4”

They are exactly what I need, very easy to use!!!

Everithing was really good, fast delivery, product quality 100% guarantee

Very versatile label for mailing addresses and a marketing to promote a product or get someone’s attention.