Removable Film Labels

Written by: Beichen Lu

|

|

Time to read 4 min

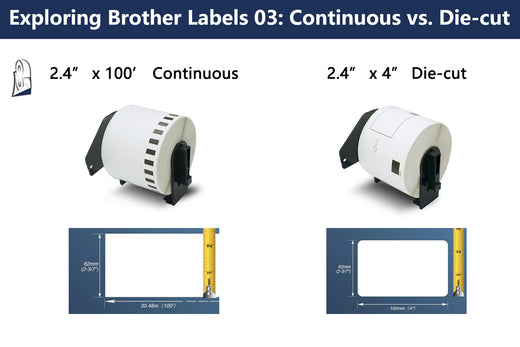

In the last blog, we discussed why Brother direct thermal labels are popular. One of the main features of Brother labels is their unique continuous design. Thanks to Brother's direct thermal printer's unique auto-cut feature, Brother offers not only die-cut labels like those of other major brands, but also unique continuous labels, providing versatility to users.

In this blog, we will compare Brother's unique continuous labels with die-cut labels from other major brands.

Table of Content

If you look at Betckey's product catalog for labels that replace Brother thermal labels, you may find that Brother designs both continuous labels and die-cut labels at every width they offer. For example, you will find DK-2205 2.4” x 100’ continuous labels and DK-1202 2.4” x 3.9” die-cut labels. There are also DK-2243 4” x 100’ continuous labels and DK-1241 4” x 6” labels. Brother understands your need for special-sized labels.

If you are a heavy user of direct thermal labels, you must have experienced difficulty sourcing special sizes like 4" x 12". On one hand, most direct thermal sellers catering to customers don’t offer these sizes due to low demand. On the other hand, you might not be able to meet the minimum order quantity for size customization.

However, Brother labels come to the rescue with their auto-cut printer and continuous labels. But who will cut the labels when you print content at your designed size? No need to manually cut them because Brother printers with their auto-cut feature will do it for you.

Brother continuous labels offer several benefits to users, but at what cost? One interesting aspect is that the trade-off of continuous labels is the benefit of die-cut labels. Since continuous labels have more labels per roll due to no gaps, they are not as easy to peel off as die-cut labels with gaps.

Furthermore, when users have tasks that don't require label separation, using continuous labels can be slower because they need to wait for the printer to cut them, otherwise, users cannot use those labels.

Brother continuous labels offer several benefits to users, but at what cost? One interesting aspect is that the trade-off of continuous labels is the benefit of die-cut labels. Since continuous labels have more labels per roll due to no gaps, they are not as easy to peel off as die-cut labels with gaps.

Furthermore, when users have tasks that don't require label separation, using continuous labels can be slower because they need to wait for the printer to cut them, otherwise, users cannot use those labels.

Die-cut labels are easier to peel off from the backing paper compared to continuous labels. When you look at die-cut labels compatible with Brother printers, you will notice that there are gaps between every single label. These gaps are not only designed for easy peel-off but also help users to remove labels from the backing paper easily. In other words, the backing paper of all die-cut labels is larger than the facestock or the part that's easy to peel off.

On the other hand, when Brother printers cut continuous labels, the facestock has an identical size as the backing paper with no gap, making it much harder to peel off the facestock from the backing paper. This can bring more efficiency to tasks that require sticking a large volume of labels without label separation.

When users are faced with tasks involving sticking a large volume of labels without the need for separation, die-cut labels excel. For continuous labels, users have to wait for the Brother printer to cut every single label, making it difficult to peel off the facestock from the backing paper and stick it. Die-cut label users, on the other hand, can print all the labels in a large volume at once and easily stick each single label to the target surface.

Don’t forget there are labor costs for all users dealing with large volumes of packages. When your warehouse staff is sticking a large volume of labels, you definitely want them to stick as many labels as possible considering their hourly wages. On the other hand, you still want your staff to stick labels as quickly as possible even if they are paid per quantity, because of the opportunity cost. If the staff finish the task earlier, you may still catch up with the FedEx pickup for the day.

With its auto-cut function printer and auto-select function labels, top-notch print app various slection of labels, Brother is one of the best brands that provide convenience to its users.

However, the trade-offs is the price due to more production cost and shipping fee.

If you want to buy thermal labels or sticker paper, you can check out more on our store

Products Featured In This Blog

No. All labels mentioned are not waterproof.

No. All these are not handwritable.

No. These labels are only compatible with Brother QL printers.

24/7 support team

Multiple Payment Methods

Worry-free shopping

Delivery in 3-7 business days

Be the first to know about label discounts,

product launches, and time-saving tips — subscribe now!

Are you 18 years old or older?

Sorry, the content of this store can't be seen by a younger audience. Come back when you're older.

I love these labels. Easy to print. Great quality. I order them all the time. Great value, too.

Very fast and professional service. Great quality labels.

When will we receive our Talladega, Al. order?

We use these labels for Amazon UPC and they work fantastic!

We are very happy with the product and value for our small business

Camaj Fiber Arts.com