Printing stickers requires more than just choosing an adhesive-quality finish. Other factors play an equally crucial role, and understanding the differences among matte, glossy, and vinyl sticker papers can help you select one best suited to your needs.

Note about glossy paper: For optimal viewing results, view it under cooler lighting (like daylight) so you can clearly view its backliner and distinguish between printing and cutting sides of a sheet. This will also help with making accurate cuts.

High Quality Inks

The quality ink and sticker paper combinations are key to producing impressive printing results, producing vivid and clear stickers while increasing durability for long-term use. Therefore, when selecting a printer to produce custom stickers for your business, ensure they use high-quality inks.

Other than print quality, other important factors to keep in mind when selecting a sticker printer include:

- Capacity and speed of production

- Compatibility with other devices

- Durability and adaptation to various materials (such as vinyl and cloth )

With this flexibility, you can craft stickers tailored specifically to your artistic vision.

When choosing a sticker printer, it's important to keep in mind that there are various kinds of models on the market with different characteristics and functions. Some are optimized for digital inkjet or laser printing, while others can accommodate solvent or aqueous-based inks.

If your business requires large-format stickers, the best printer would be one with inkjet capabilities capable of printing onto thicker sheets of printable sticker paper and producing vibrant and detailed colors - such as an inkjet printer - to enhance their visual appeal.

If you want to print smaller, less complex stickers, laser printers may provide durable water-resistant products. Lasers utilize toner instead of ink and are more reliable and durable than their inkjet counterparts.

Additionally, lasers produce higher resolution prints due to their higher resolution capabilities and offer different paper weight options that may better meet your specific requirements.

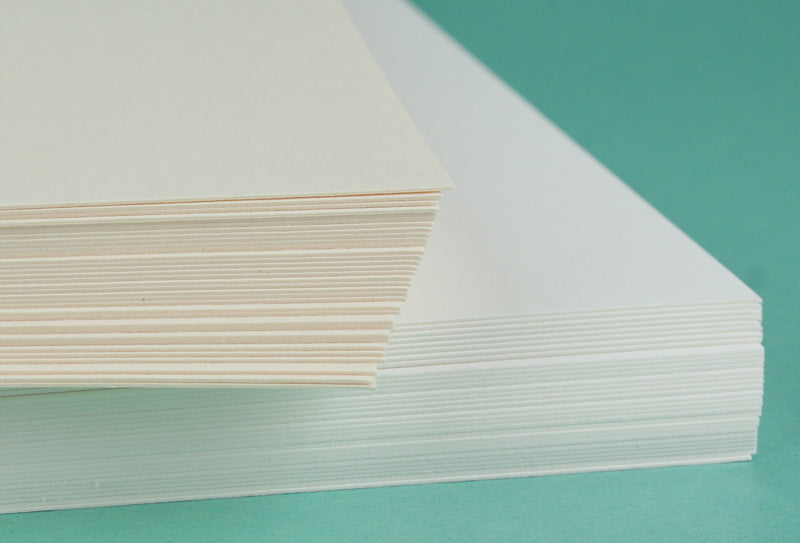

Sticker Paper Weight

Selecting the ideal paper weight is crucial to both the quality of your stickers and compatibility with your printer. Gram weight refers to the thickness and stiffness of a single sheet of label paper, measured either as g/square meter (gsm) or points/mil (Points Per Inch). As its gram weight rises, so too does its rigidity and thickness.

The weight of the paper has an immediate impact on its print quality. It determines its ink absorption capacity, making vibrant prints without smudges. Furthermore, its smooth feed through printers prevents jams or misfeeds.

Thick paper typically features a smooth surface that makes printing high-resolution graphics and text with sharp edges easier, as well as being more durable and resistant to water damage. However, sometimes thinner paper may be more suitable, for instance, when used temporarily such as for event flyers.

Thicker paper has more surface area for ink absorption. Unfortunately, this increases printing costs and slows print speeds. Laser printer users may experience internal parts scraping the page while printing, leading to blurred images or clogged printer heads that require costly repairs.

Before using your laser printer, ensure it can handle the thickness of paper stickers you plan to use before attempting to print with it. Also check that it offers manual feeding - bypassing its paper tray altogether by hand feeding - while setting lower print quality settings will lower ink usage while protecting against paper sticking together or smudging issues.

Once your stickers are complete, the best way to protect them from moisture or direct sunlight damage is by laminating. You can do this either with clear laminating sheets that adhere directly to the stickers or by running them through a thermal laminate machine.

Either way, you will end up with high-quality, waterproof sticker paper that will surely stand the test of time.

Sticker Printer Paper Type

Selecting the proper sticker paper plays an integral part in ensuring the quality of your prints. The suitable label paper for printer can ensure your designs and texts appear clearly without blurring or distortion, while it is important to remember that different printer models require different requirements for sticker paper.

The material used in creating adhesive paper can have a dramatic impact on its durability and printing performance. Some papers are created specifically to be more durable or for high performance applications.

Other types may feature glossy finishes to improve visual appeal or provide better smudge resistance - these features are particularly valuable to businesses that use stickers for marketing or business reasons.

Selecting the appropriate sticker paper for your printer can ensure that prints come out crisp and clear, free from smudging or other defects. To reduce smudges, it's best to wait until the ink has completely dried before handling it. Additionally, smudge-resistant papers often feature coatings designed to stop ink from bleeding through their surfaces.

Matte, clear, and white paper can all make great sticker papers. Matte offers an elegant appearance due to its non-reflective surface while clear uses transparent PVC or PET to provide see-through effects when printed, making it suitable for window decals, overlays, and other applications where an underlying surface must be visible.

Based on your requirements, Betckey sticker paper offers an earthy and rustic aesthetic, making it suitable for printable adhesive paper projects with earthy or rustic themes.

It is easy to cut and adheres securely to flat surfaces. Full sheet label sizes make this type of paper suitable for simple printing projects, while some Betckey stickers may work with both inkjet and laser printers.

Adhesive Properties

A high quality adhesive will help your prints adhere tightly and securely, helping to maintain shape and appearance over time. When selecting adhesive properties for sticker papers, consider both their intended applications and surfaces; different adhesives may suit certain materials better. You may have to experiment until you find what best meets your needs.

Surface texture and porosity play an integral part in determining your sticker paper's adhesive performance.

A smooth or glossy paper can make printing on it more challenging, while a rougher matte option may offer better adhesion for stickers attached to various surfaces. Rough surfaces could lead to ink smudges or cause other printing-related problems.

While you might be tempted to purchase pre-printed sticker paper, using electronic cutting machines may save both money and effort while creating more customized looks.

These convenient tabletop units allow for precise cutting with minimum effort while creating unique shapes or intricate designs with unique shapes or intricate patterns. Cricut and Silhouette are two widely known brands.

Quality sticker printing paper depends on many different elements, which include:

- Material and thickness

- Color options

- Durability

Focusing on these features can ensure your stickers withstand various environmental conditions for an impactful and long-lasting visual presence.

Finding the ideal sticker paper can be an enjoyable and straightforward process. By exploring your options and reading customer reviews, you can select an item that meets both your individual printing requirements and needs.